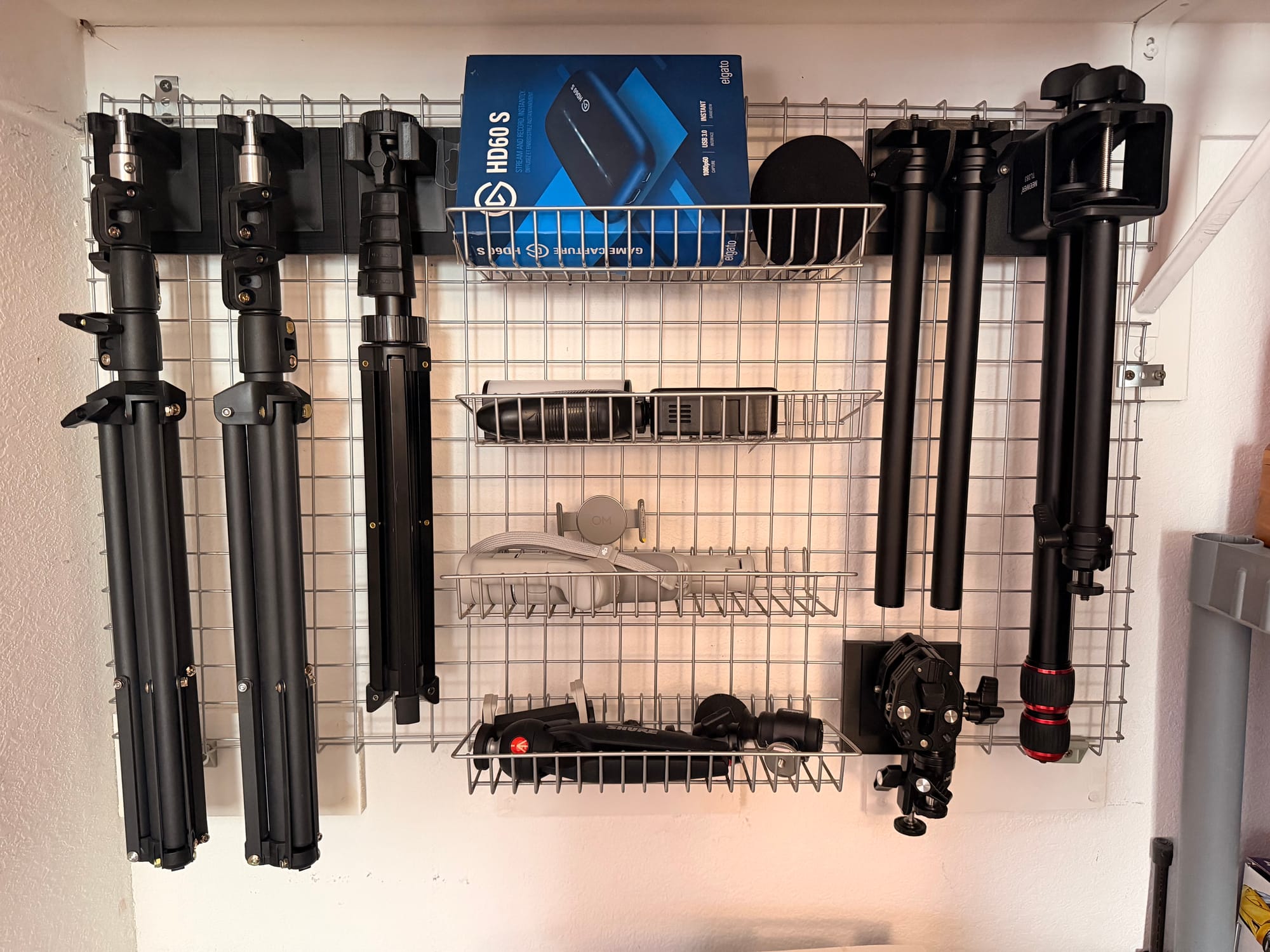

I have arguably too many gadgets and gizmos for my YouTube channel, most of which I use infrequently but were taking up valuable real estate in my desk drawers. While I know there are already tons of modular systems out there (like Multiboard) I had a few specific goals with this project:

- Get hands on experience designing my own objects

- Repurpose part of an existing storage system

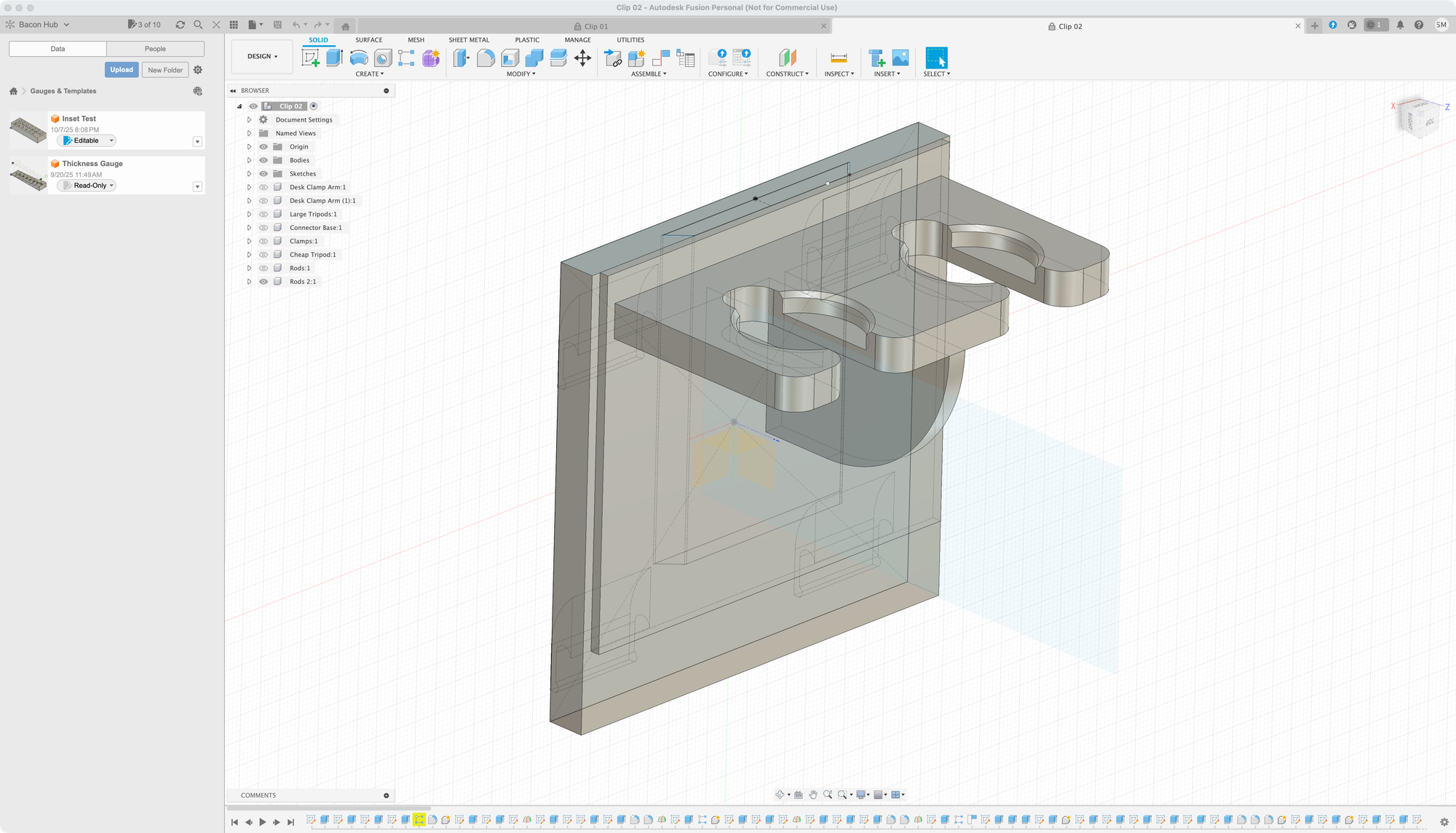

- Design for modularity, to cut down on print time, and with layer direction in mind (WTR the strength of the model and supports)

I got a crash course in print tolerances, support design, and layer direction in this project. But all in all this came together without too much trial and error. And snapping the bases onto the grid or a bracket into the base happens with a VERY satisfying click. Bonus ASMR.

Here are a few shots that show the final product along with some closeups of the custom parts. Each “bracket” shares a standardized base that clips onto the wire grid. I designed each bracket to connect to the generic base meaning I only have to reprint half of the part if I want to swap in a new custom organizer.

At this point I’m still not using parametric modeling to its fullest potential, but that’s fine. The goal right now isn’t perfect, it’s getting across the finish line.